Ian Urbina, October 24, 2003

Viewed on October 30, 2003On April 16, 2003, George W. Bush visited the shop floor at the Boeing plant in St. Louis, Missouri. His 90-minute appearance drew several hundred men and women who help make the military's $48 million F-18 Hornet fighters, 36 of which were deployed during the Iraq war. The purpose of Bush's visit was twofold: to offer thanks to the blue-collar workers equipping US soldiers for their foreign adventures and to provide reassurance in an atmosphere of climbing unemployment.

One week prior to Bush's visit, the St. Louis plant announced layoffs for about 250 people. Already in 2003, Boeing had eliminated 5,000 positions nationwide, in addition to the 30,000 jobs the company cut in 2002. Bush's so-called "Hardware in the Heartland" tour, which included stops across the industrial Midwest, was part of a post-war campaign strategy to capitalize on the US military prowess demonstrated in Iraq. "Sure, he talked about his domestic agenda," a White House official told Time magazine concerning the Boeing appearance, "but there were F-18s in the background."

But the "Hardware in the Heartland" tour skipped a number of locales where thousands of hard-working men and women were contributing more than their share to the war effort. While the Boeing employees sat listening to Bush's remarks, just 50 miles to the northeast 265 workers in the apparel factory in Greenville, Illinois were far from idle. Averaging more than 1,000 desert-tan camouflage shirts per day, 194,950 of which were bought in 2002 by the Department of Defense and worn by the US infantry in the Middle East, these workers were not allowed many breaks. Equally harried were the 300 workers at the Kevlar helmet factory in Beaumont, Texas, who fill 100 percent of the US military's demand for battlefield headgear. A factory in Marion, Illinois also kept in rapid motion, soldering millions of dollars worth of cables for the Pentagon's TOW and Patriot missiles. Presidential plaudits were not forthcoming for these workers -- all of whom are inmates in federal prisons.

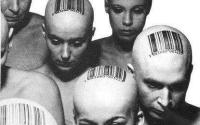

Captive Labor Force

Were it not for this captive labor force, the military could hardly meet needs ranging from weapons production and apparel manufacture to transportation servicing and communications infrastructure. US soldiers are well-equipped with guns to fire, clothes to wear, vehicles to drive, radios to call and maps to help them navigate, thanks in large measure to the 21,000 inmates working for Federal Prison Industries (FPI), a quasi-public, for-profit corporation run by the Bureau of Prisons. In 2002, the company sold $678.7 million worth of goods and services to the US government, over $400 million of which went to the Department of Defense.

Government reliance upon prison inmates for war production is hardly new. Founded in 1934, Federal Prison Industries, also known as UNICOR, started lending a hand in WWII, as prison factories ran two and three shifts per day for military manufacturing, increasing output threefold before the armistice was declared. In four years, FPI produced more than $75 million worth of everything from aircraft to dynamite cases, parachutes, cargo nets and tents, all for shipment to troops in the European and Pacific theaters. As early as May 1941, the Atlanta federal penitentiary alone was producing eight to ten train carloads of war materiel per day. During the Korean War, 80 percent of FPI output went to defense, with sales reaching over $29 million, and the number of inmates employed by the corporation topped an unprecedented 3,800. More recently, FPI has been no less vital. During the 1990-91 Persian Gulf conflict, inmates produced belts, camouflage battle-dress uniforms, lighting systems, sandbags, blankets, night vision eyewear, chemical gas detection devices and bomb components. Even after the September 11 attacks, inmates took a role in relief work; their labor supplying virtually all the protective goggles worn by recovery staff at the New York and Pentagon sites.

No Ordinary Contractor

Over the years, FPI has grown exponentially, now ranking as the government's thirty-ninth largest contractor -- in no small part due to the quantity and diversity of apparel items it manufactures for the Department of Defense. The company has churned out more than 150,000 Kevlar helmets in the past 24 months, more than $12 million worth. Aside from the battle-dress shirts sewn at Greenville, the company is also a major supplier of men's military undershirts, $1.6 million of which it sold to the Pentagon in 2002. In that year, FPI made close to $3 million fashioning underwear and nightwear for the troops. Inmates also stitch together the vestments donned by military pastors and the gowns cloaking battlefield surgeons. If an item of clothing is torn in combat, it will likely be sent to the prison shop in Edgefield, South Carolina, where it is mended at a cost of $5 per shirt and or pair of trousers. In 2002, 700 prisoners based at FPI laundry facilities located in Florida, Texas and Alabama washed and pressed $3 million worth of military apparel.

Federal inmates also do their part to ensure that US forces are never outgunned. FPI factories produce a variety of components for weaponry ranging in size from 30mm to 300mm, the caliber of battleship anti-aircraft guns. FPI is there to help with more sophisticated hardware as well. To bombardiers and gunners in training, the company supplies practice targets and devices used to simulate battle conditions. In the lead-up to the 1991 Gulf war, inmates at the Marion facility and elsewhere ramped up production of cable assemblies for Patriot missiles. More recently, the company broadened its output to include the remote control panels, as well as the launchers, for the TOW and other guided missile systems. It is not just the technology that has developed over the years. Though there has been no formal and updated review, most military officials report that the workmanship of FPI's weapons parts has improved markedly since the early 1990s, when a Defense Department inspector found that FPI cables sold to the Army failed at nearly twice the rate of the military's next worst supplier.

In today's military, virtually all ground troops are equipped with small microphone headsets which wire them to each other and to off-site command centers. FPI sold $7 million worth of essential components for these headsets to the Defense Department in 2002 -- but this is only a tiny fraction of the company's massive business with communications procurement officials at the Pentagon. FPI has 14 prison factories employing more than 3,000 inmates manufacturing electronics equipment. In 2002 alone, these workers crafted $30 million worth of the wire assemblies that go into all types of land, sea and airborne communication systems. Inmates working for FPI also provide the Defense Department with thousands of dollars worth of services in mail sorting, and the company averages more than $4 million per year in printing services, generating everything from letterhead and envelopes to military maps, calendars and training manuals.

Unfair Competition

From Humvee repair to the manufacture of millions dollars worth of electrical cords for the Army, FPI offers a wide array of goods and services. But along the way, FPI has picked up a bevy of critics. One of the foremost complaints about the company stems from the unusual legal relationship it maintains with the US government. According to the legislation that founded FPI in the era of President Franklin D. Roosevelt, the company enjoys a special "mandatory source status" which requires federal agencies to buy its products even if the same items can be purchased cheaper elsewhere. Many businesses claim that this special status gives FPI undue competitive advantage.

In 1997, this issue came to a head. After FPI doubled its stake in the military glove market over the course of several years, private glove manufacturers joined with a range of other apparel and furniture makers to fight the unfair competition. Supporting their outcry was the Defense Personnel and Support Center, in charge of most of military's apparel purchasing, which complained that FPI's products were on average 13 percent more costly than those of commercial companies. Eventually, a General Accounting Office investigation revealed a pattern of higher prices, slower delivery and lower quality goods from FPI than from the private sector.

Though problems remain, most Defense purchasing representatives interviewed (none of whom would speak on the record) report that FPI has cleaned up its act significantly, while the mandatory source requirements have also been loosened. In the case of the glove industry, the company agreed to avoid taking more than $7 million of the government contracts.

Still, FPI's relationship with the non-prison labor market remains strained. The company's driving purpose is to turn a profit in order to offset costs in the expensive prison system, while also bolstering prison security by keeping close to 25 percent of the inmate population as busy as possible. But with the prison population skyrocketing, FPI struggles to find enough new products and consumers to keep its work force occupied. FPI's competitors in the textile industry are in no less of a bind, with more than 200,000 jobs heading overseas since 2001. Increased trade with China, a country infamous for its prison labor, has decimated the industry, leaving many domestic manufacturers on the defensive. Imports now account for at least 70 percent of US glove sales. Since the Defense Department is required to buy US-made goods, it is one of the few remaining safe havens where glove and other apparel makers can retreat from overseas sweatshop and prison labor competition.

FPI's military glove production is not the only source of controversy. Skeptics also point angrily to the desert-tan battle trousers worn by the troops in Iraq and elsewhere in the Middle East. Out of the 1.3 million pairs of these trousers bought by the Defense Department last year, all but 300,000 were produced by FPI, which means that at least three out of four active-duty soldiers in the region wear pants made by the inmates of the FPI factories in Atlanta and in Beaumont and Feagoville, Texas. These sorts of numbers have earned FPI critics from a range of perspectives. FPI competitors, such as Propper International, point out that they use free labor to make the exact same trousers for the government at $2.39 cheaper per pair. Organized labor questions why the government should buy from a company which depends solely on inmate workers, while paying sub-minimum wages (from 25 cents to $1.15 per hour), skirting workplace safety standards and enjoying exemption from the payroll and Social Security taxes levied on other employers.

In 1997, FPI lost a rare battle when, due to the "volume and tenor" of complaints, it withdrew plans to begin making American flags at its jailhouse tailor shops. FPI had completed a thorough market study, and the bulk of its flags were to be destined for the Veterans Administration, to be draped over coffins at military funerals.

Meese Vs. China

FPI argues, and some studies support its contention, that its work programs not only help with prison security, but are also superior to old-fashioned prison activities like breaking rocks, since manufacturing jobs equip inmates with job skills they can use upon their release. Most inmates jump at the chance for a job with FPI, since it is one of the few legal ways to earn money while incarcerated. However, the question remains whether these for-profit programs have an overall adverse effect on the prospects for rehabilitation of prisoners. Where prison factories can turn a profit, there is less incentive to invest in more expensive ways to fill the time, such as counseling, drug treatment and literacy programs. In California, for example, where prison for-profit work programs are increasingly popular, inmate educational and vocational programs have been cut statewide by almost 20 percent, with a loss of roughly $35 million for prison educational spending and 300 fewer prison teachers.

Some advocates of for-profit prison labor, like Edwin Meese of the Enterprise Prison Institute, contend that programs like those of FPI have a huge potential to boost the economy. While serving as attorney general under President Ronald Reagan, Meese oversaw the implementation of stiffer sentences for drug offenders -- a major cause of the historic swelling of the US prison population. In Meese's view, if inmate work programs were reformed in the right way, they could avoid competing with free American workers, while beating countries like China at their own game. By expanding for-profit prison factories, but limiting them to the production of items that would otherwise be produced in foreign sweatshops or prison factories, the US could actually stem the flow of jobs and profits abroad. Critics respond that such plans drive wages down at home for free workers, while also undermining the potential for useful job training for inmates, since the majority of the repetitive and low-skill jobs which inmates hold are the very same jobs which will all be either overseas or inside the prisons by the time an inmate is released.

Politics Of Exploitation

FPI's military production raises security concerns as well. Some wonder if the Defense Department's over-dependence on inmate labor will dry up the nation's so-called "warm industrial base," a term referring to the small commercial manufacturers that specialize in stepping up production during times of war. They fear that as these small specialty factories disappear, the military runs the risk of being caught with its pants down if prison riots or inmate work stoppages should happen to coincide with future drives toward military intervention.

Inmates are often involved in highly sensitive work involving the physical safety of soldiers in the field. In 2002, FPI earned $12 million in sales of body armor to the Defense Department, and in 1999 inmates patched holes in $30,000 worth of faulty parachutes. There is no security screening to work in FPI factories. As an experiment, Middle East Report contacted three of the men convicted for the bombing of the World Trade Center in 1993. Two had not only worked in FPI factories, but also reported being compelled to do so. Mohammad A. Salameh put up a long legal fight before he was finally excused from working for the company. Salameh pointed out that since he, along with more than 29 percent of the total federal prison population, is not even a legal resident of the United States, he should not be legally permitted -- much less forced -- to work for the company. Ultimately, when the Bureau of Prisons released Salameh from the job, they admitted in court documents to having forced him to work for FPI. Officials argued that the compulsory labor was justified since higher-risk inmates were easier to monitor if they were kept busy. Under such policies, it certainly seems that the potential and incentive for sabotage of FPI's military products would be high. Ironically enough, it is such practical and security concerns which could eventually weaken FPI's grip on production for the Pentagon.

As the US occupation of Iraq stretches on with nary an "exit strategy" in sight, however, it is hardly surprising that the politics of prison labor are also nowhere in view. Neither the period of occupation nor prison production offers much in the way of telegenic triumphs for White House politicos to exploit. Around the same time that US troops north of Baghdad were storming Saddam Hussein's notorious Abu Ghraib prison (where, in another grim irony, the US is now detaining many hundreds of Iraqis), George W. Bush was winding up his "Hardware in the Heartland" tour with a stop in Santa Clara, Calif., to rally the employees of United Defense, builders of the Bradley Fighting Vehicle. A raucous cheer ran through the crowd when Bush noted that the company also produces the Hercules tank recovery vehicle, one of which had played a starring role in the war's most famous (and famously staged) cinematic tableau -- the toppling of a statue of Saddam Hussein in Firdous Square in central Baghdad.

With American casualties mounting in Iraq, and little good news about domestic employment either, even the Bush campaign must understand that a reprise of such photo-op moments would be in poor taste. So the 21,000 inmate employees of FPI, despite their vital importance to Bush's wars, remain distinctly behind the scenes.

Ian Urbina is a reporter for the New York Times and former associate editor at the Middle East Research and Information Project.